Disposal, Scrapping & Recycling Lithium Batteries

Recycling lithium batteries is important for mitigating environmental impact and conserving valuable materials. With the growing demand for lithium-ion batteries, especially in electric vehicles and mobile phones, the need to effectively recycle electric vehicle batteries has never been more pressing.

Recycling batteries, particularly lithium-ion, ensures that we recover valuable materials like nickel, cobalt, and copper, which are essential for producing new batteries. See also our article on recycling lead acid batteries.

Growth of Lithium Battery Usage and Environmental Impact

The widespread adoption of rechargeable batteries, particularly lithium-ion batteries, in mobile phones, computers, and electric vehicles, has led to significant environmental concerns. Lithium ion battery recycling is important in mitigating these environmental impacts by addressing the challenges and complexities involved in the recycling process, including safety risks and the environmental implications of improper disposal.

As more lithium batteries reach the end of their lifecycle, improper disposal can result in serious fire risks, pollution, and loss of raw materials. These batteries contain metals like lithium, nickel, and cobalt, which, if not recycled, contribute to environmental degradation and resource depletion.

As the battery market expands, the environmental impact of discarded batteries becomes increasingly severe, making recycling an essential component of sustainable development.

Types of Lithium Batteries and Their Chemical Composition

Understanding the types of lithium batteries and their chemical composition is key to effective recycling. The most common types include lithium-ion, nickel-cadmium, and nickel metal hydride batteries.

Lithium-ion batteries, used in most consumer electronics and electric vehicles, contain a mix of metals, including lithium, nickel, cobalt, and metal oxides. These materials are valuable but also pose recycling challenges due to their complex chemical structure.

By identifying the specific components in each battery type, recycling facilities can more effectively recover valuable materials and minimize environmental impact.

| Type of Lithium Battery | Chemical Composition | Common Applications | Key Characteristics |

|---|---|---|---|

| Lithium-Ion (Li-ion) | Lithium Cobalt Oxide (LiCoO2), Lithium Manganese Oxide (LiMn2O4), Lithium Nickel Manganese Cobalt Oxide (LiNiMnCoO2) | Mobile phones, laptops, electric vehicles | High energy density, lightweight, long cycle life, requires protection circuit |

| Lithium Iron Phosphate (LiFePO4) | Lithium Iron Phosphate (LiFePO4) | Electric vehicles, power tools, solar energy storage | Stable chemistry, long cycle life, safer than other Li-ion types, lower energy density |

| Lithium Polymer (LiPo) | Lithium-ion in polymer electrolyte | RC models, drones, portable electronics | Flexible form factor, lightweight, moderate energy density, sensitive to damage |

| Lithium Nickel Cobalt Aluminum Oxide (NCA) | Lithium Nickel Cobalt Aluminum Oxide (LiNiCoAlO2) | Electric vehicles, industrial applications | High energy density, long life span, used in Tesla vehicles, higher cost |

| Lithium Titanate (LTO) | Lithium Titanate (Li4Ti5O12) | Electric buses, solar energy storage, UPS systems | Fast charging, long cycle life, excellent safety, lower energy density |

The Recycling Process: From Collection to Reuse and Disposal

The recycling process for lithium-ion batteries involves several critical steps, from collection to safe disposal. First, batteries are collected from recycling bins, transfer stations, and hazardous waste service providers. After collection, they undergo sorting to separate different battery types. The next step is the removal of battery terminals and the dismantling of embedded batteries from devices like mobile phones and computers.

Once sorted and dismantled, batteries are processed to recover valuable materials. This involves shredding the batteries into small pieces, followed by processes like pyrometallurgy or hydrometallurgy to extract metals such as lithium, nickel, and cobalt. The remaining material, known as “black mass,” is further processed to recover any remaining metals. This recycling process not only prevents environmental pollution but also reduces the need for raw material extraction, promoting a circular economy.

| Step | Description |

|---|---|

| 1. Collection | Batteries are collected from recycling bins, transfer stations, and hazardous waste service providers. |

| 2. Sorting | Batteries are sorted to separate different battery types, ensuring proper handling and recycling methods. |

| 3. Removal of Battery Terminals and Dismantling | Battery terminals are removed, and embedded batteries from devices like mobile phones and computers are dismantled. |

| 4. Shredding | Batteries are shredded into small pieces to prepare them for material recovery. |

| 5. Material Recovery (Pyrometallurgy/Hydrometallurgy) | Processes such as pyrometallurgy or hydrometallurgy are used to extract valuable metals like lithium, nickel, and cobalt. |

| 6. Processing of “Black Mass” | The remaining material, known as “black mass,” is further processed to recover any remaining metals. |

| 7. Reuse and Safe Disposal | Recovered materials are reused in the production of new batteries, while non-recyclable components are safely disposed of. |

Key Players in the Lithium Battery Recycling Industry

The lithium battery recycling industry is supported by key players, including battery manufacturers, recycling companies, and governmental bodies. Major battery manufacturers like Tesla and Panasonic have invested in recycling initiatives to reclaim valuable materials from used batteries. Specialized recycling companies, such as Li-Cycle and Redwood Materials, focus on efficiently recycling lithium-ion batteries and recovering metals for reuse in new batteries.

Governmental bodies also play a crucial role by setting regulations and providing incentives for recycling, which drives the industry forward.

Environmental Impact of Lithium Battery Recycling

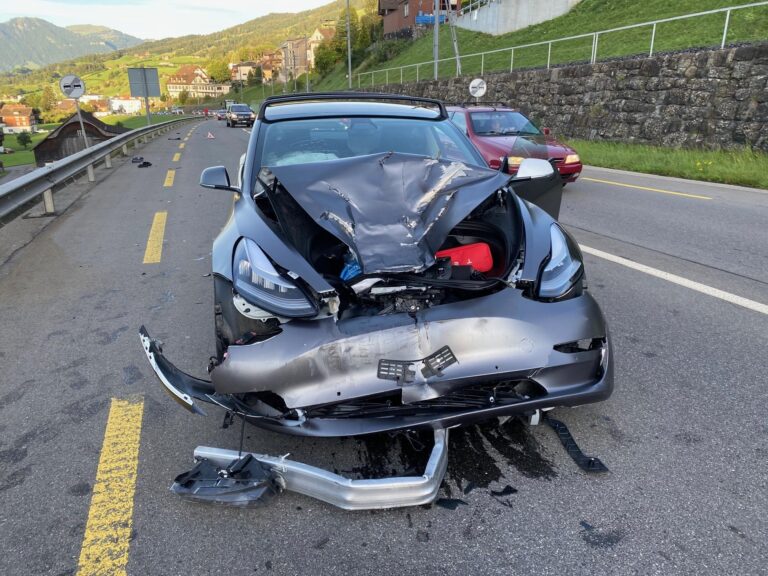

Recycling lithium-ion batteries significantly reduces their environmental impact by preventing hazardous waste from entering landfills and recovering valuable materials for reuse. The improper disposal of batteries can lead to off-gassing of toxic chemicals, pollution of soil and water, and a serious fire risk, especially in transfer stations and garbage trucks.

Properly recycling batteries ensures that metals like nickel, cobalt, and lithium are recycled and reused, minimizing the need for new mining operations and reducing the overall carbon footprint. This process also helps to mitigate the risk of short circuits and other fire hazards associated with battery waste.

Economic Benefits and Challenges of Lithium Battery Recycling

The economic benefits of recycling lithium batteries are substantial, though not without challenges. Recycling batteries reduces the cost of raw materials for battery manufacturers, as recycled metals like nickel and cobalt can be reused in the production of new batteries.

This contributes to cost savings and resource conservation in the battery market. Additionally, the recycling industry creates jobs and stimulates economic growth, particularly in regions where recycling facilities are established.

However, the challenges are significant. The complexity of the recycling process, the need for advanced technology, and the safe handling of hazardous materials make recycling lithium-ion batteries a costly endeavor. Also, the volatility of raw material prices can impact the profitability of recycling operations. Despite these challenges, the long-term benefits of recycling batteries outweigh the costs, making it a vital part of the battery industry’s future.

Current Technological Advancements in Lithium Battery Recycling

Technological advancements are driving improvements in the recycling of lithium-ion batteries. The role of a recycling facility is crucial in enhancing safety measures, reducing the risk of fires, and improving Australia’s recycling capabilities. Innovations like robotic disassembly and advanced material recovery processes are making it easier to recycle batteries and recover valuable materials efficiently.

Direct recycling, which preserves the battery’s structure, is emerging as a promising method for recycling lithium-ion batteries without the need for complete disassembly.

These technologies not only improve the recycling process but also reduce the fire risk and environmental hazards associated with traditional recycling methods. For instance, new processes are being developed to handle mixed metal dust and other byproducts safely, preventing contamination and ensuring that all recyclable materials are effectively recovered.

Regulatory Frameworks Governing Lithium Battery Recycling

Regulations play a crucial role in shaping the lithium battery recycling industry. International, national, and local regulations dictate how batteries should be recycled and disposed of. In many regions, strict guidelines are in place to ensure that batteries are not disposed of in household bins, where they pose a serious fire risk. Instead, they must be taken to designated recycling facilities or hazardous waste service providers.

Incentives for recycling, such as subsidies for recycling companies or mandates for battery manufacturers to take back used batteries, further encourage the growth of the recycling industry. These regulations not only ensure safe disposal and recycling but also promote the recovery of valuable materials, contributing to the sustainability of the battery market.

Case Studies of Successful Recycling Programs and Initiatives

Successful recycling programs around the world offer valuable insights into best practices for lithium battery recycling. For example, in the European Union, strict regulations require the recycling of a significant percentage of all batteries sold, leading to the establishment of advanced recycling facilities and the development of new recycling technologies.

In the United States, companies like Redwood Materials are pioneering efforts to recycle lithium-ion batteries from electric vehicles and consumer electronics, recovering valuable materials that can be reused in the production of new batteries.

These programs highlight the importance of collaboration between industry, government, and consumers to achieve effective recycling outcomes.

The Future of Lithium Battery Recycling

The future of lithium battery recycling is bright, with continued advancements in technology, regulatory support, and industry collaboration. As the demand for rechargeable batteries, especially in electric vehicles and mobile phones, continues to grow, the need for efficient recycling processes will become even more critical.

By addressing the challenges of recycling and embracing new technologies, the industry can ensure that lithium-ion batteries are safely recycled, valuable materials are recovered, and environmental impacts are minimized. This will not only support the sustainable growth of the battery market but also contribute to the broader goal of a circular economy, where resources are conserved, and waste is minimized.

Popular Questions

Below are some common questions we get asked about this topic.

What happens if lithium-ion batteries are not recycled properly?

If lithium-ion batteries are not recycled properly, they can pose serious environmental and safety risks. Improper disposal can lead to toxic chemicals leaking into the soil and water, contributing to pollution. Additionally, these batteries can cause fires if damaged or improperly handled, especially in household bins or garbage trucks. Proper recycling ensures that hazardous materials are safely managed and valuable resources are recovered.

How can consumers safely recycle lithium-ion batteries?

Consumers can safely recycle lithium-ion batteries by taking them to designated recycling facilities, transfer stations, or participating retailers that offer battery recycling services. It’s important not to dispose of these batteries in household bins, as this poses a fire risk. Many communities also have hazardous waste collection events where used batteries can be safely dropped off for recycling. Always check local guidelines for proper battery disposal to ensure safe and responsible recycling.