The Car, Truck Other Vehicle Recycling Process

Vehicle recycling is a complex and important part of managing end of life vehicle (ELV). This process not only reduces waste and conserves natural resources but also ensures that hazardous materials are handled in an environmentally friendly manner. We look at the detail the entire vehicle recycling process, from the initial collection to the final recycling of materials.

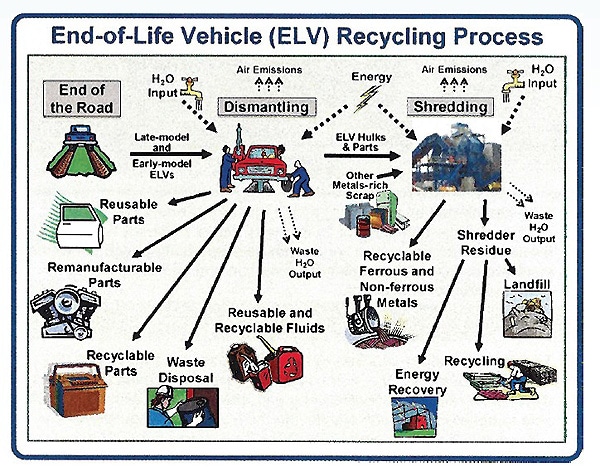

Image source: https://recyclingportal.eu/Archive/67774

Introduction

The vehicle recycling process starts with the collection of end of life vehicles. Scrap car recycling plays an important role in this process, highlighting the importance of professional recyclers in transforming old vehicles into valuable raw materials. This process is integral to the car recycling industry, which focuses on reducing the environmental impact of old vehicles by reclaiming usable materials and responsibly disposing of hazardous substances.

Collection and Transportation

Collection of End of Life Vehicles

The process begins with the collection of scrap cars from various sources, including salvage yards, individual owners, and auto parts stores. Recycling facilities and recycling companies often collaborate with these sources to ensure a steady supply of vehicles for recycling. Scrap car recycling plays a crucial role in efficiently transforming old vehicles into valuable raw materials, highlighting its environmental and economic impact.

Transportation to Recycling Facilities

Once collected, scrap cars are transported to specialized recycling facilities. These facilities are equipped to handle the various stages of the recycling process, including the safe removal of hazardous materials.

Initial Processing

Dismantling and Depollution

At the recycling facility, the first step involves dismantling the vehicle. Skilled technicians remove all hazardous substances such as engine oil, brake fluid, and catalytic converters. This responsible disposal of hazardous materials is critical for environmental protection and complies with strict regulations.

Removing Usable Parts

Next, valuable and reusable car parts are removed. Components such as engines, transmissions, and batteries are extracted for further processing or direct resale. This step not only supports sustainable practices but also creates a market for recycled materials in the automotive industry.

Shredding and Separation

Shredding the Vehicle

After dismantling, the remaining vehicle shell is fed into a large shredder. This machine reduces the vehicle to small, shredded materials, making it easier to separate different materials.

Separation of Materials

Post-shredding, the recycling process involves separating the shredded materials into various categories such as ferrous metals, non ferrous metals, and other materials like plastics and glass. Recycling technologies such as magnetic separation and eddy current separators are used to achieve this.

Recycling the Separated Materials

Recycling Metals

Ferrous metals and non ferrous metals are sent to steel mills and other processing facilities where they are melted down and repurposed into new materials. This step is important for producing recycled metal, which is then used in manufacturing new cars and other products, significantly lowering carbon emissions.

Recycling Other Materials

Plastic parts, glass, and precious metals are also recycled. For instance, plastics are processed into raw materials for new plastic products, while glass is crushed and reused in various industries. This comprehensive approach ensures that almost every part of the vehicle contributes to reducing landfill waste.

Final Processing and Quality Control

Final Processing

Once the primary materials are separated, they undergo further processing to ensure they meet quality standards for reuse. This stage includes cleaning, refining, and preparing materials for industrial use.

Quality Control

Quality control is a vital part of the recycling process. Recycling facilities implement stringent quality checks to ensure that recycled materials meet the necessary standards for safety and usability. This step is essential for maintaining the integrity of the recycling industry and ensuring that recycled materials can be effectively used in new manufacturing processes.

Final Notes

The vehicle recycling process is a sophisticated and essential part of modern resource management. By understanding each step, from the collection of end of life vehicles to the recycling of raw materials, we can appreciate the industry’s role in reducing the environmental impact of old vehicles.

This process not only conserves valuable natural resources but also supports sustainable practices and reduces greenhouse gas emissions, paving the way for a greener future. Additionally, Australian car recycling plays a significant role in the economic, environmental, and cultural landscape, highlighting its systematic approach and contribution to the economy.